[ad_1]

Should you’re going to kill animals for meals, don’t waste their components – that’s simply impolite. Use every little thing, snout-to-tail, and never simply bones for glue or stomachs for drink-bags, both. Get inventive!

So if Futurama’s Bender had his fingers amputated, you could possibly improvise replacements after a single journey to Purple Lobster. Don’t consider me? Take a look at the next creepily hilarious video of lobster tail shells became robotic “fingers.” They undoubtedly work higher than Jamie Lee Curtis’s scorching canine fingers did in All the things In every single place All At As soon as. And robots may even swim with them!

Bio-hybrid robots flip meals waste into practical machines

And why not? Crustacean shells are sturdy and versatile, renewably sourced, and so stunning that designers at Apple ought to take notes. Numerous industrial designers are impressed by biomimicry, however they use plastic, steel, and composites to create parts formed like organic constructions, moderately than utilizing these precise constructions in their mechanisms.

That’s why the brand new lobster tail design is so progressive. The experimental gripper from the Computational Robotic Design and Fabrication Lab (CREATE Lab) on the College of Engineering in Switzerland’s École Polytechnique Fédérale de Lausanne (EPFL) makes use of a pair of lobster tails as twin fingers, as mentioned in an Superior Science paper with the beautifully sinister sea-punk-sounding title “Lifeless Matter, Residing Machines: Repurposing Crustaceans’ Stomach Exoskeleton for Bio-Hybrid Robots.” As a result of it makes use of precise animal tissue, this “hand” isn’t bio-mimicked. It’s bio-derived.

2025 CREATE Lab EPFL CC BY SA

“Exoskeletons mix mineralized shells with joint membranes,” says co-author Josie Hughes, head of CREATE Lab, which suggests they provide “a steadiness of rigidity and adaptability that permits their segments to maneuver independently. These options allow crustaceans’ fast, high-torque actions in water, however they will also be very helpful for robotics. And by repurposing meals waste, we suggest a sustainable cyclic design course of by which supplies will be recycled and tailored for brand spanking new duties.”

Hughes’ level about meals waste (an unlimited drawback which New Atlas has coated in quite a few articles) is greater than merely meals for thought. As United Nations Local weather Change stories, meals waste (which was 1.05 billion tons in 2022) is answerable for 8-10% of world greenhouse gasoline emissions – and prices the planet a trillion {dollars} – yearly. Any repurposing of biowaste for good use decreases the technology of methane from anaerobic degradation in landfills (a catastrophe that the US Environmental Safety Company nimbly explains on this information).

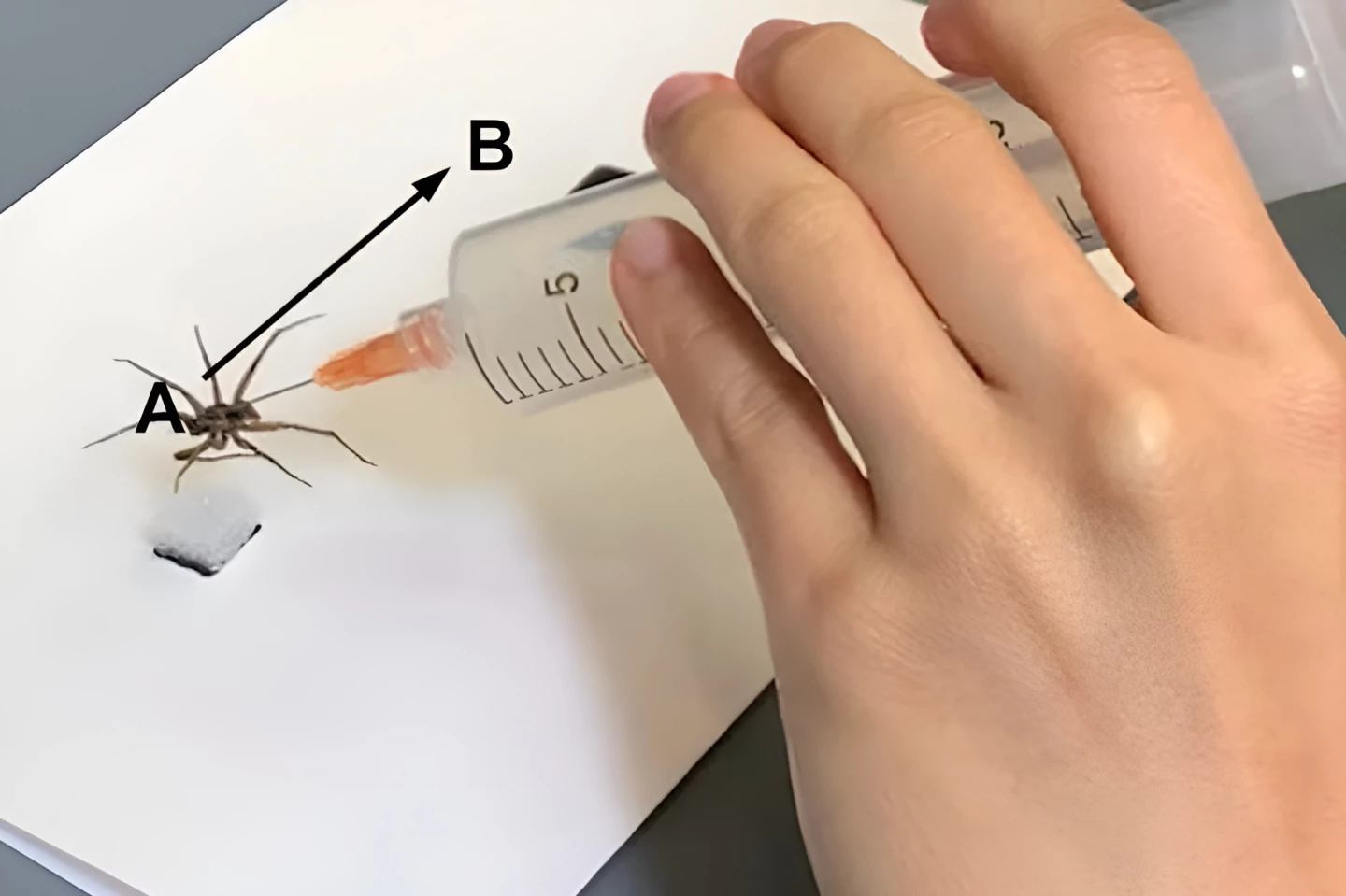

This is not the primary time scientists have used components from useless animals for mech-hands. New Atlas reported on spider-based “necrobotic grippers” from Texas’ Rice College (which due to their dimension would really make an excellent utensil for consuming rice). However with a lifting capability of 500 g (1.1 lb), the lobster-fingers might heft a dinner of steak and lobster.

Preston Innovation Laboratory/Rice College

They’re additionally supple sufficient to know objects of varied styles and sizes (together with highlighter pens and tomatoes) with out crushing them, because of an embedded, segment-controlling elastomer that, mounted on its motorized base, flexes and extends the “fingers.” With a reinforcing silicone coating to make sure longevity, the tails are prepared for motion – even (no shock, given their supply) as components for robots that swim at as much as 11 cm (about 4 inches) per second.

Better of all, following use, recyclers can separate the lobster and robotic components and maintain the artificial parts for different functions. “To our information,” says CREATE Lab researcher and the paper’s lead writer Sareum Kim, “we’re the primary to suggest a proof-of-concept to combine meals waste right into a robotic system that mixes sustainable design with reuse and recycling.”

In fact, in contrast to manufacturing facility components, lobster tails aren’t standardized, and as an alternative develop in quite a lot of dimensions which bend in another way, and so the researchers clarify that future designs would require tunable controllers and different superior artificial augmentation mechanisms. If such improvements are profitable, bio-derived units might function implants and monitoring platforms.

As workforce lead Hughs says, nature “nonetheless outperforms many synthetic techniques and presents helpful insights for designing practical machines based mostly on elegant rules.”

Supply: EPFL

[ad_2]