[ad_1]

Information briefs for the week check out drones selecting fruit, Ocado’s next-gen logistics system, micro-plating lab cobots, seafloor robots amassing trash, no-code Wandelbots, and robots disrupting wire harness business.

Drones as flying fruit pickers

Drones, often categorized primarily as our eyes within the sky or for delivering packages, now have an actual “hands-on” job: flying fruit pickers.

Israel-based Tevel Aerobotics Applied sciences builds what it calls FARs for Flying Autonomous Robots a/okay/a quadcopter drones. FARs, whereas tethered to an influence provide, use a imaginative and prescient system, AI/ML, three-foot-long, light-weight robotic arm with selecting gripper to select solely

The quadcopter FARs make the most of laptop imaginative and prescient and AI to detect fruit and foliage, whereas figuring out fruit sort, measurement, and ripeness. Throughout off-harvest months, the FARs are able to performing further duties like pruning, trimming, and thinning of orchard timber.

With harvesters, particularly fruit-picking employees, turning into ever extra in brief provide worldwide, which the pandemic has exacerbated, Tevel sees as a possibility to market its patented FAR platform. VC investments appear to agree as Tevel has picked up a latest $20 million, including to a earlier $20 million from a January funding spherical.

“Our robots have glorious maneuverability – they will maneuver with six levels of freedom,” says founder and CEO, Yaniv Maor. “This permits us to select nearly all of the fruit from timber, work with completely different orchard structure — comparable to thick and skinny timber, trellis methods, and spherical timber — and to select many sorts of fruit with the identical {hardware}.”

Growers can customized order any variety of FARs needed, specify an actual variety of days for harvesting (the FARs decide 24/7, day and evening), and be assured that solely ripe fruit are picked. With labor historically practically 50% of an orchard’s working bills, FARs considerably pare down or get rid of employees altogether.

Ocado slims down robots and grid

Ocado jumps out with Collection 600 next-gen AMR: light-weight, simpler to assemble, partially constructed with 3D printers, and operating on a grid community that’s additionally lighter, and takes “weeks relatively than months” to put in, claims Ocado.

Every of its Collection 600 AMR are constructed from over 300 3D-printed elements, making for important value to construct and time to construct reductions, with an total weight per robotic the business’s lightest thus far.

On the unveiling, Ocado’s CEO Tim Steiner additionally unveiled a brand new on-AMR robotic arm to help with selecting and inventory administration. “Utilizing machine imaginative and prescient, deep reinforcement studying and superior sensing, the arm helps the general decide and pack grocery by selecting grocery objects proper on the grid”

Steiner additionally claimed that the brand new “On-grid Robotic Choose” will result in decrease labor prices, increased achievement throughput and warehouse optimization features.

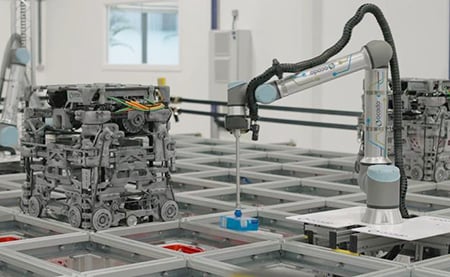

New 4-axis cobot for lab micro plating

The 4-axis SCARA-type cobot “designed particularly for all times science analysis” takes on the exacting, repetitious drudgery of lab microplate stacking.

The Spinnaker’s robotic imaginative and prescient functionality and specialised software program, which includes a location verification routine, allow straightforward configuration and/or instructing of automation options, together with built-in, vision-assisted instructing and barcode studying that allows computerized affirmation of pattern identification (see video).

The 4-axis SCARA’s “versatile attain, infinite rotation and full gravity-neutral joints facilitate positioning when instructing or integrating devices.” The cobot’s digital camera “can see points that end in misplaced samples and cycle time earlier than they grow to be issues.”

Robots as seafloor, trash-collection system

Though there are a selection of floor expeditions working to take away the estimated 26 to 66 million tons of seaborne plastic waste, most of it, nicely over 90%, is much from the floor, like on the ocean flooring.

Within the clear water off Dubrovnik (Croatia), the SeaClear system, consisting of 4 robots every with a special however suitable job, succeeded at finding and capturing 90% of backside trash. Additional trials are scheduled within the port of Hamburg in Could 2022.

The system combines 4 robots: an autonomous floor car to sonar scan the ocean flooring to find massive litter pockets. An remark robotic is then lowered to get close-up pictures to transmit to computer systems for evaluation. A set robotic then hones in on computer-defined targets and extracts the littler, bringing it to the floor.

“We don’t have the computing energy at our disposal that we might on dry land,” says Prof. Sandra Hirche, director of the chair and SeaClear principal investigator. “We do not need hyperlinks to massive information facilities with supercomputers. So, we’d like extremely environment friendly algorithms that run with restricted sources. We’re due to this fact working with high-efficiency sampling strategies that arrive at exact predictions with minimal information. The AI system merely discards pointless info.”

Hamburg is an efficient take a look at. Based on the Christian Science Monitor, Hamburg’s harbor is murky and harmful, and far of the ocean flooring is filled with trash and poisonous silt.

If SeaClear succeeds there, it’s a lifetime of labor in harbors worldwide.

Wandelbots’ no-code robots

Dresden-based Wandelbots blares out on its homepage: “With Wandelbots Educating you may simply educate robots new abilities with out writing a line of code—as straightforward as 1 – 2 – 3.”

Wandelbots has been busy exhibiting its true believers and others that it’s potential “to deploy a robotic military with out the necessity for lots of out of doors assist, important sums of cash and/or robotic coding know-how.”

Wandelbots has a magic wand it calls the “TracePen,” which is used to imitate a movement, any movement, to coach a robotic in that movement’s course of. After the preliminary coaching is roughed out with the pen, it may then be fine-tuned with software program with out the necessity to apply coding.

In a latest interview, Annelie Harz, advertising and marketing supervisor from Wandelbots, mentioned “we’re progressively integrating the biggest robotic manufacturers into our platform.” Yaskawa is one. “We will definitely additionally combine smaller robotic manufacturers that cowl a number of niches. Or, even higher, because of our Robotic Integration Software program Growth Equipment, robotic producers will quickly have the ability to do it themselves.”

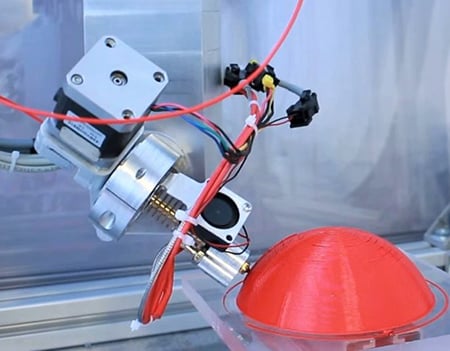

5-axis robotic to “rework wiring business”

Amazingly, wiring harnesses for electronics—for the whole lot from fridges to vehicles to flat-screen TVs—are principally nonetheless made by hand. Complexity has been the primary purpose. UK-based startup Q5D Expertise experiences that it’s disrupting the century-old hand crafting of wiring harnesses to “pace up the method of producing, decrease prices and mitigate human error.”

Q5D’s tech answer, referred to as the CU500, is a 5-axis robotic and interchangeable polymer, silver and copper-compatible printheads that may be tailored for the speedy deposition of both polymers, metallic pastes or wiring.

The CU500 may very well be used to create wire harnesses and so as to add conductive tracks to elements—even these with complicated geometries—to intricate digital gadgets, or family home equipment or onto massive aerospace and automotive elements (see video).

Based on Q5D Expertise, the CU500, due to its interchangeable printhead, permits it “to modify from depositing polymers or pastes to finishing up sintering, embedding or jetting on a single built-in platform.”

The CU500 system “allows the machine so as to add layers to current elements in a conformal style, unlocking the manufacturing of steady prints with complicated 3D shapes.”

A latest $2.5 million funding spherical will likely be used to additional the event of a extra superior multifunctional wiring and electronics 3D printer.

[ad_2]